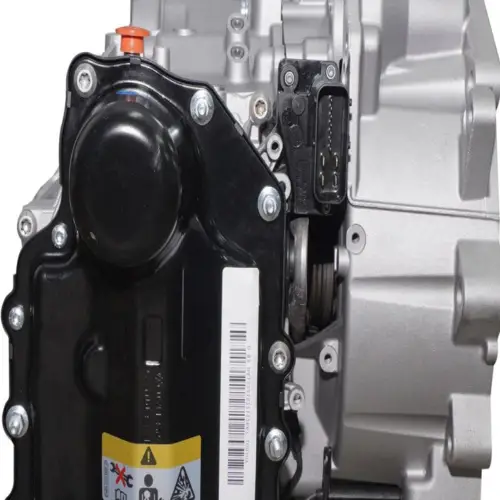

DQ200 Dual Clutch 7 Speed OAM Automatic Transmission Gearbox for VW Audi Air Compressor Oil

Are you in need of a high-quality, remanufactured DQ200 OAM OAM927769D DSG 7 Speed Auto Spare Parts Automatic Transmission Gearbox with 2 Clutch for your VW or Audi? Look no further than our company! Our remanufactured transmission gearbox is the perfect solution for your automotive needs.

Product Description

Our 7 Speed Dual Clutch Automatic Gearbox is designed to be compatible with various types of Audi and VW models, including the Audi A1, A3, and VW Caddy, Golf, Jetta, Passat, and more. With OE Number OAM927769D, this automotive spare part is a reliable and cost-effective alternative to OEM parts.

Our remanufactured workshop ensures that all of our products are of the highest quality, and our gearbox is no exception. We undergo a rigorous process that includes deep disassembly and cleaning of all components, replacement of commonly used vulnerable parts with new ones, upgrading and improving existing quality defects, and strict inspection and calibration of all components to ensure that the testing standards have been verified by actual vehicles. Additionally, we provide comprehensive programming and after-sales tracking services.

Our 7 Speed Dual Clutch Automatic Gearbox comes with a one-year warranty and has a MOQ of only one piece. We offer fast delivery within 15 workdays, and our customer service team is always available to answer any questions you may have.

Main Products

In addition to our 7 Speed Dual Clutch Automatic Gearbox, our company also offers a wide range of auto transmission assembly and components. These include gearboxes, clutches, valve bodies, valves, computers, electromechanical assemblies, release bearings, shafts, flywheels, valve oil, oil seals, filter elements, and more.

Applicable Brands

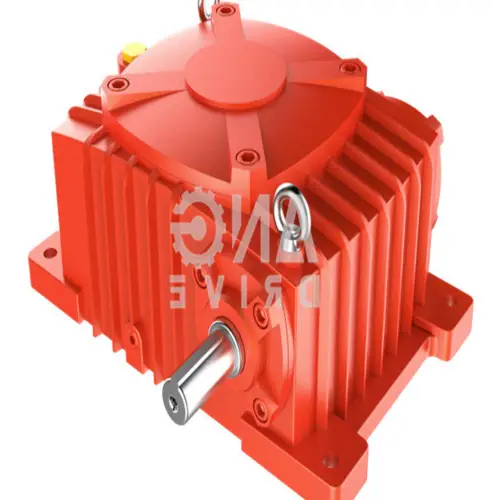

We supply a variety of auto parts for various brands of automobiles, like VW, Audi, Cadillac, Hyundai, Chevrolet, Zotye, etc. Our products are suitable for industrial use and are extensively used in agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

FAQs

1. What is a dual-clutch automatic gearbox?

A dual-clutch automatic gearbox is a type of automated manual transmission that uses two separate clutches for odd and even gears. This allows for faster and smoother gear shifts than traditional automatic gearboxes.

2. What is remanufacturing?

Remanufacturing is the process of taking a used product or component and restoring it to like-new condition. This process includes disassembly, cleaning, replacement of worn or damaged parts, and reassembly to meet OEM specifications.

3. What is the OE number for this product?

The OE number for our 7 Speed Dual Clutch Automatic Gearbox is OAM927769D.

4. How long is the warranty for this product?

We offer a one-year warranty for our 7 Speed Dual Clutch Automatic Gearbox.

5. Can I customize the product?

Yes, we welcome customers to provide their own drawings and samples for customization.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy.

Introduction

Gearbox, also known as transmission, is an essential component that plays a significant role in transmitting power from the engine to the wheels in a vehicle. The performance characteristics of the gearbox are as follows:

1. Transmission Efficiency: The gearbox has high transmission efficiency, which can ensure that the engine’s power is transmitted to the wheels in a more efficient way.

2. Torque Multiplier: The gearbox can also act as a torque multiplier, which can increase the torque output of the engine to the wheels.

3. Gear Ratio: The gearbox can change the gear ratio, which can provide a wide range of speeds for the vehicle.

Types and Characteristics of Gearbox

There are several types of gearbox, including manual, automatic, continuously variable, and dual-clutch gearbox. Each type has its unique characteristics that suit different driving conditions.

1. Manual Gearbox: This type of gearbox requires the driver to change the gear manually. It is simple, reliable, and cost-effective, making it popular in many vehicles.

2. Automatic Gearbox: This type of gearbox can change gears automatically, making it more convenient for drivers. It is also suitable for reducing fuel consumption and improving driving comfort.

3. Continuously Variable Gearbox: This type of gearbox can continuously change the gear ratio, making it more fuel-efficient and smoother in operation.

4. Dual-Clutch Gearbox: This type of gearbox has two clutches, which can provide quick gear changes and improve driving dynamics.

Advantages of Gearbox Made of Different Materials

The gearbox can be made of various materials, including aluminum alloy, cast iron, steel, and magnesium alloy. Each material has its advantages and disadvantages.

1. Aluminum Alloy: This material is lightweight, which can reduce the overall weight of the vehicle and improve fuel efficiency.

2. Cast Iron: This material is durable and can withstand high loads, making it suitable for heavy-duty applications.

3. Steel: This material is strong and can resist wear and tear, making it suitable for high-speed applications.

4. Magnesium Alloy: This material is lightweight and has good heat dissipation, making it suitable for high-performance applications.

Application of Gearbox

The gearbox is widely used in various industries, including the automotive industry, industrial machinery, agricultural equipment, wind turbines, marine applications, and many others. Its use reflects its value and importance in various fields.

Future Development Trends and Opportunities

The gearbox industry is continuously evolving, and there are many development trends and opportunities in the market. Some of these trends include:

1. Lightweight and Compact Design: The demand for lightweight and compact gearbox design is growing due to the need for more fuel-efficient vehicles.

2. Electrification: As more vehicles become electrified, there is a growing demand for electric gearbox systems that can handle higher torque loads.

3. Advanced Materials: The use of advanced materials, such as carbon fiber, can improve the strength and durability of the gearbox.

How to Choose a Suitable Gearbox

Choosing a suitable gearbox requires consideration of several factors, including load requirements, ratio selection, type of gearbox, environmental factors, maintenance, and durability.

1. Load Requirements: The gearbox should be selected based on the load requirements of the application. This includes the weight of the vehicle, the torque output of the engine, and the maximum speed of the vehicle.

2. Ratio Selection: The gearbox should be selected based on the desired gear ratio. This includes the number of gears and the gear ratios of each gear.

3. Type of Gearbox: The type of gearbox should be selected based on the driving conditions and the vehicle’s purpose.

4. Environmental Factors: The gearbox should be selected based on the environmental factors, such as temperature, humidity, and vibration.

5. Maintenance and Durability: The gearbox should be selected based on its maintenance requirements and durability.

Conclusion

In conclusion, the gearbox is an essential component in various industries, and its performance characteristics, types, materials, and applications make it a vital part of many vehicles and machines. The future development trends and opportunities in the gearbox industry are promising, and choosing a suitable gearbox requires careful consideration of several factors.